15 years one-stop China custom CNC machining parts factory

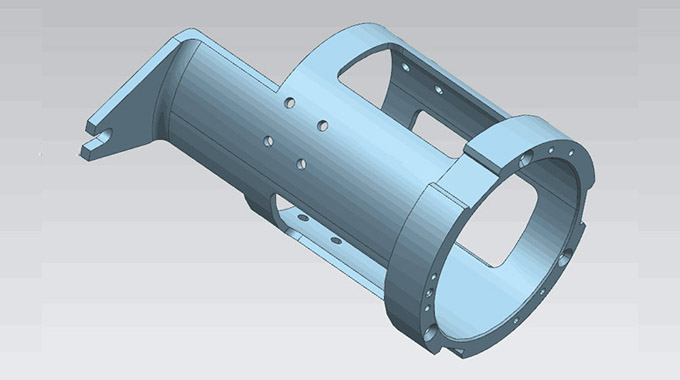

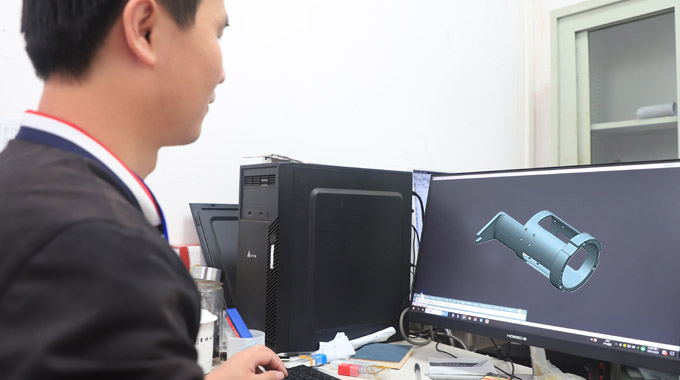

Based on the special product and the above reasons, CNC Machining processing cost is too high, so our engineering decided to change the method.

| Item | Original processing method | Existing processing methods |

| Processing methods | Direct 5-axis machining | Design extruded profile drawing according to prototype |

| Order materials according to drawings | ||

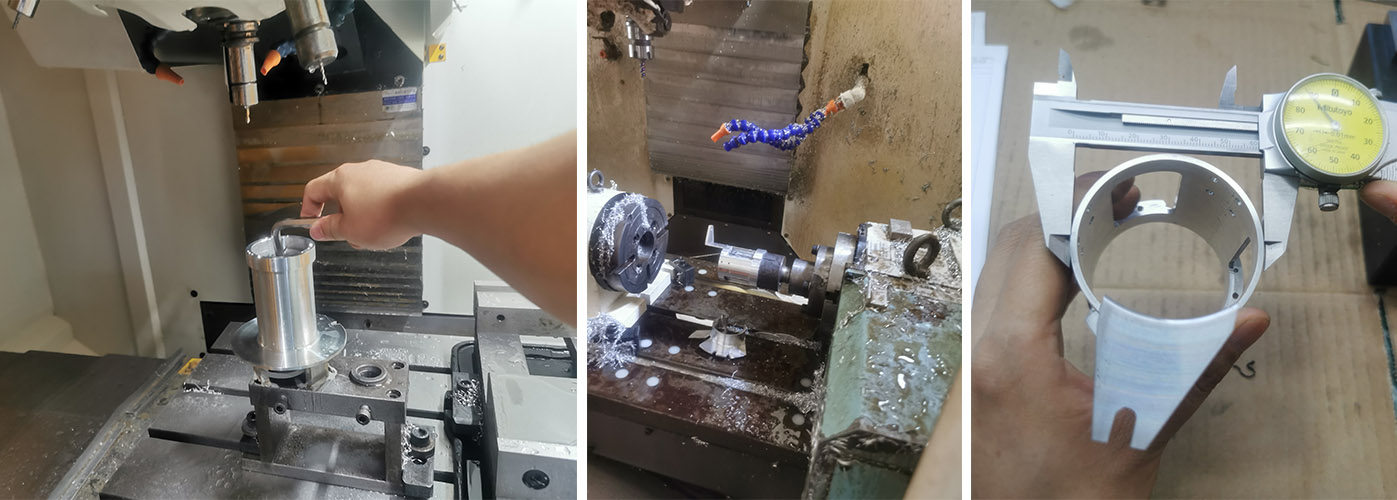

| Machining the first process with a CNC lathe | ||

| After the fixture is installed, place it on the 3+2 machine for processing | ||

| Pros and cons | Long processing time | Save materials and reduce processing time, saving 20% of costs |

Manufacturing processes

Tolerance detection

package

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!